NEW CABABILITIES BROCHURE

Contact us for more information at sales@artechengineering.com

DIE LOADING ANALYSIS SIMULATION (DLAS)

Artech Engineering Inc (AEI) is currently developing a system to upload press tonnage data for detailed loading reviews. This system will regularly check mechanical and hydraulic press loading. Maintaining proper loading will extend the life of your presses. This system follows the IoT architecture. Contact us for more information.

MOVABLE BRIDGE ENGINEERING SUPPORT

Engineering support includes translation of repair planning documents into manufacturing drawings with complete details and bill of materials. Old documentation is typically converted to 3-D solid designs.

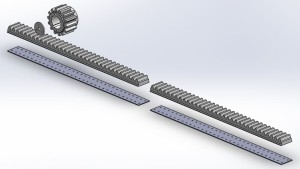

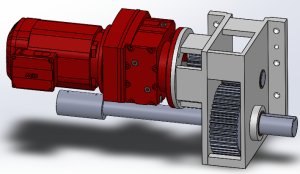

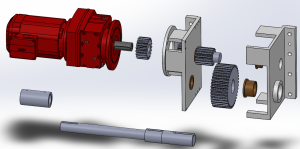

DESIGN AND MODIFICATIONS TO DRIVE TRAINS

We provide detailed Engineering Analysis and Design for special drive trains that include linkage components, shafting, gears, bearings, cams, keyways, and special mounting requirements. These designs are used in existing drives to modify torque capacity and speeds, or for new concept clean sheet design requirements.

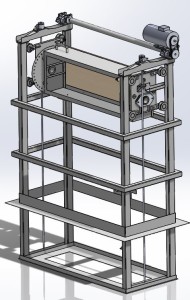

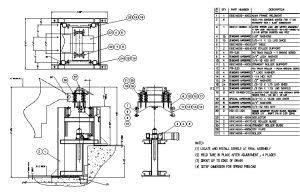

CUSTOM AUTOMATION USING SOLIDWORKS

Artech Engineering Inc (AEI) has developed this design concept working directly with the end user. All activities up until the final installation were supported by AEI. The Design, Engineering Analysis, Bill of Material, and Manufacturing Details were generated using SOLIDWORKS. The design allows for rotation and moving an enclosure from one floor of a building to the next floor below.

SOLIDWORKS 2016

Artech Engineering Inc has SOLIDWORKS premium for design, Engineering Analysis (FEA), and documentation capabilities.

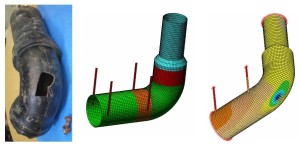

Machine Upgrade

After our field investigation, the problem component was replaced with a drop in upgrade. The new design was validated using FEA.

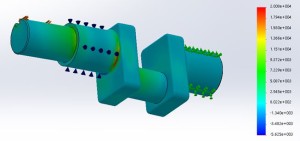

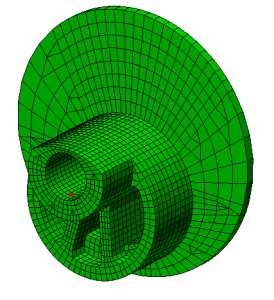

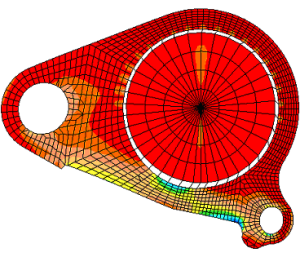

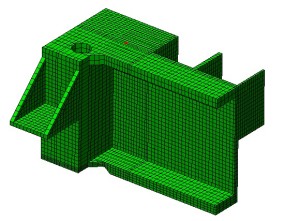

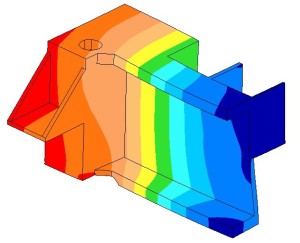

Kinematics and Finite Element Analysis

Artech Engineering Inc has conducted Engineering studies that integrates kinematic data with Finite Element Analysis so that complete load histories are considered. The following press drive component is part of a special linkage that applies full tonnage across three points of support. The large bore includes non-linear interface elements (gaps) for a more accurate solution.

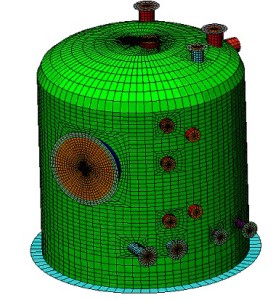

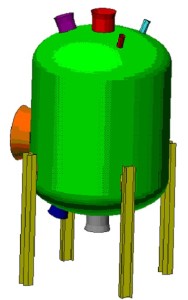

Pressure Vessel Engineering Analysis

Capabilities include FEA integrated with the ASME Sec VIII Div 2 code for cyclic count determination. Special applications in the past included the DDAM procedure for the Navy.

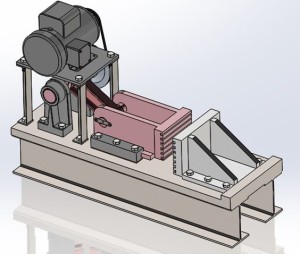

Machine Design / Heavy Equipment / Automation

Artech Engineering Inc provides all types of product and machinery design. This sample system was a “clean sheet” development to create a series of conveyors and walking beams that separates bundles of tubing for a paint line.

Press Engineering Capability

Artech Engineering Inc has over 30 years of press design experience. Utilizing Engineering Analysis methods with this experience, we determine root cause of failures and develop design upgrades.

Hydraulic Solution for Forming Dies

Retro fit system provides better control of binder pressure during metal forming. Based on hydraulics, this system provides a controllable forming force throughout the press stroke and eliminates upward loading post bottom.

Failure Analysis

Utilizing classical theoretical Engineering Analysis methods and the computer simulation method Finite Element Analysis, the root cause of the failure is determined

Power Transmission Studies

Artech Engineering Inc provides studies and analysis reviews of drive trains and drive train components. Reviews include torque and force determination for purposes of size determination.